“LEAN in the company is like the sea, you need a good captain to run smoothly, even during a storm (such as COVID’19 )”

PhD Monika Zadłużna

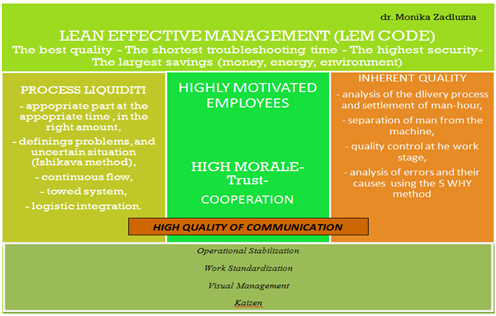

LEAN MANAGEMENT = ELIMINATION OF ERRORS AND LOSSES

In business, a long-term advantage is important, which in turn consists of developing unique competences based on know-how, experience and innovative solutions in a shorter period of time. In recent years, the concept of Lean Management (LM) has become the knowledge initiating the indicated distinguishing features. The genesis of the area of knowledge contained in this name is related to the activities of the well-known Japanese company Toyota, and its Production System (TPS) is the nucleus of the Lean concept.

Lean management is defined as lean management and is a concept of enterprise management based on adapting it to the current market conditions. The main goal of Lean is to accelerate the flow of processes by reducing waste. Thanks to the management taking into account the principles of lean manufacturing, Toyota has increased the flexibility of its operations and improved the quality of manufactured products offered in a faster time than the competition. It happened through continuous improvement, work monitoring and waste removal. Perfecting in production, over time, it also went beyond its scope, namely into back office tasks, and this is how lean management in offices was created. Lean improvement is the elimination of unnecessary things, processes both in office work and in production.

To this day, the use of LM applies to, among others, the following processes: placing orders and planning, creating technical drawings, production, administrative services, employing employees, etc. The conclusion is that the LM cycle can be applied to any type of production or service activity, production and service. It is worth noting, however, that in the current research areas in the field of LM, the names of several sectors of the economy that significantly affect GDP are still missing. Extending research in the area of Lean Effective Management in companies and industries for which a given concept is a novelty, and most importantly, publishing a report on the effects of its application will certainly bring unmeasurable effects in terms of both measurable and and immeasurable. And as I often say – IT’S WORTH BEING THE FIRST READ ABOUT.

The activity of each enterprise consists of processes (equivalent to LV lines), ideas, procedures for solving problems that arise during these processes (MV lines), as well as employees and partners (HV lines). The use of BOM, reducing waste at the distinguished levels shapes the areas of improvement in the scope of, among others: defect reduction, cycle reduction, cost reduction, inventory reduction, but also reduction of their shortages, service improvement, reduction of the number of failures, reduction of failure removal time, reduction of expenditures working time, reducing employment, reducing absenteeism, improving capacity, improving system reliability, improving customer satisfaction, etc. All this contributes to increasing the efficiency of the processes taking place in the company, including mainly learning from mistakes, and further eliminating losses by using only reliable and reliable proven technology.

In every enterprise, what determines its development and its competitive advantage is investment in people as its driving energy. The philosophy of long-term thinking, which is brought by the application of LM principles, shapes the organizational culture based on respect and trust in relation to both the employee’s subject and the client. It is the employees who create interesting ideas, problem-solving procedures, and thus, effective processes are created.

Taking into account any direction of the company’s development and its long-term strategy, the introduction of LM principles will contribute to the increase in the value of enterprises. This increase will include values expressed in monetary units: incl. an increase in profit, in the case of companies listed on the stock exchange, an increase in the value of stocks, shares, and also expressed in non-measurable – qualitative value: people (employees, clients), market position, vision, strategy, development

Considering the challenges of the Polish economy, especially now in the time (hopefully in the final stage) of COVID-19, companies should look for new solutions to overcome the crisis. And in companies that have come out of this difficult time, look for solutions to problems that have arisen during COVID activities anyway. It is important in this case to use the secrets of knowledge.

According to the author, methods that are beneficial to use in the area of lean manufacturing: TPM, VSM, 5Xwhy and work standardization. On the other hand, in the area of lean office, in all business units of any industry, the following analyzes can be rationally used: 5S, VSM and the Ishikava diagram.

The indicated methods make it possible to conduct research, extrapolation and efficient organization of work, including verification of low-repeatability work methods, analysis and evaluation of time-consuming tasks, accurate and quick calculation of the time required to perform planned works or maintenance, limitations management, or the introduction of indicators effectiveness of key processes.

It is worth noting that lean management is beneficial to start with back office cells, because in an office or customer service salon, the client most often interacts with the company. Many processes are formally complex and the client does not like to wait. His choice will be focused on the subject of cooperation, which will finalize the entire process related to it qualitatively and efficiently, i.e. without unnecessary formalities and wasting his time converted into money. In this case, it is necessary to apply the principles of lean lean.

To sum up, the Lean concept as an innovative solution determining the company’s development and in the long term will be successful in the form of increasing the value of enterprises, taking into account both the financial result and reputation on the national and international arena.

The extension – LEAN, will benefit you / your company, especially in the current COVID – confusion.

“I am convinced that life is 10% of what happens to me and 90% of how I react to it”

Charles R. Swindoll,

I invite you to cooperation.

Let’s create your company’s LEM Code and spread the word about it in domestic and foreign publications.

Bibliography:

Celmerowski Z., Didactic material of Lean Six Sigma studies, Gdańsk University of Technology, Gdańsk 2020.

Czyż-Gwiazda E., Lean Management Concept in organization management, UE in Katowice, Scientific Journal No. 233, Katowice 2015.

Debtna M., doctoral dissertation entitled “The role of intellectual capital in managing an energy sector enterprise”, Poznań University of Economics, Poznań, 2016.

Introduction to Lean Office, Montana State University, Montana 2009.